Close

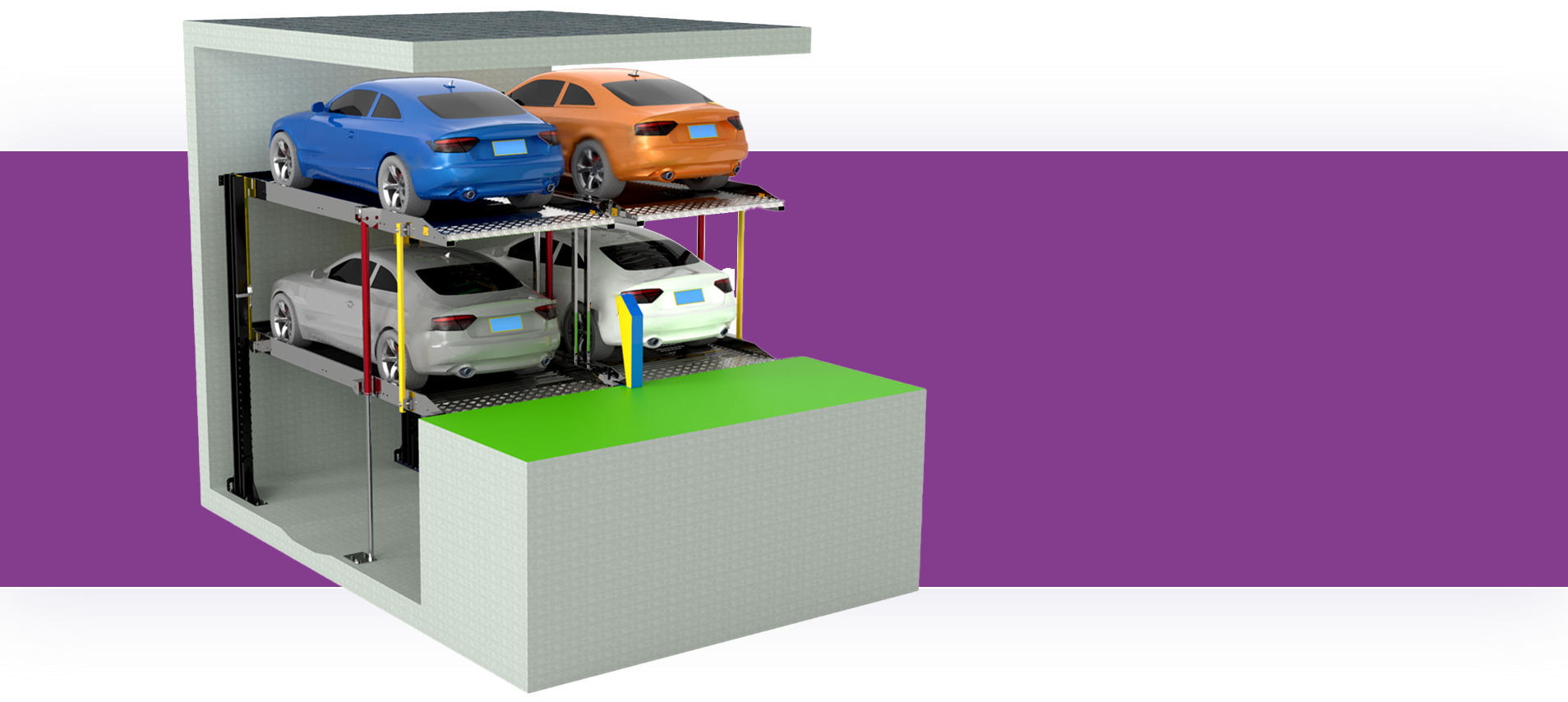

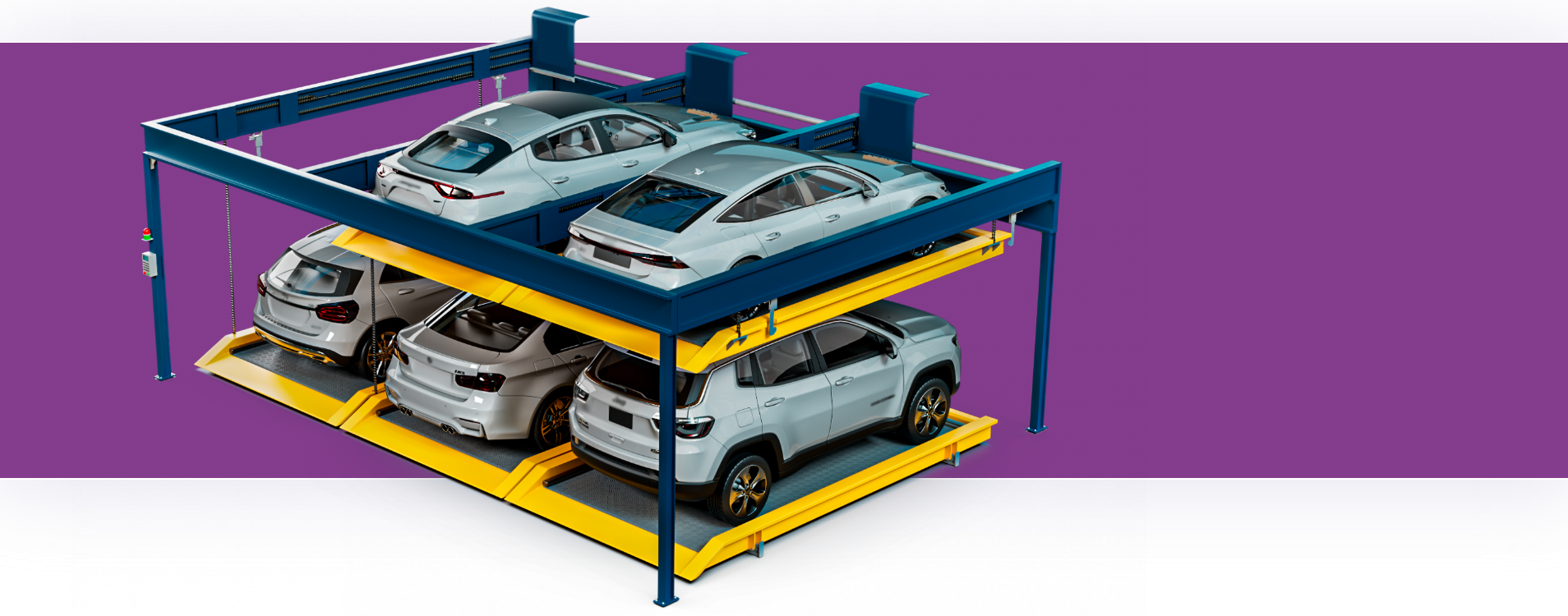

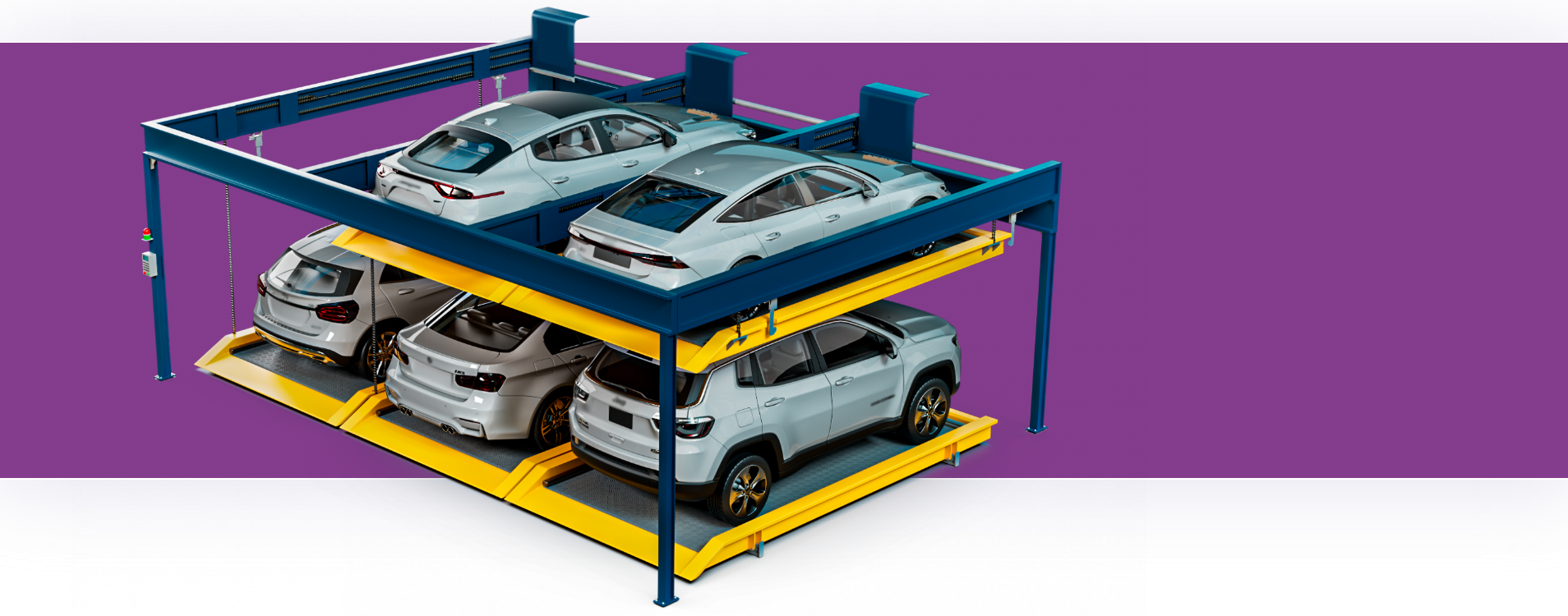

Spark’s Multilevel PIT auto parking system allows passengers to park one above the other. They have three places that are joined and raised together: top, centre, and bottom. The middle and bottom pits are buried below in the pit due to its revolutionary system, making it compact and space-saving. The top level is at the same line as the ground for direct in and out parking of the cars. All PitPark models are powered by hydraulic chambers that provide either just vertical motion or a mix of two vertical motions to its platforms.Ramps are not required for the pit car parking scheme. The ground floor just has the entry and exit lift rooms.

The basement does not require passenger elevators, staircases, or illumination. Because there is no human access to the subterranean parking spots, ventilation and CCTV coverage are not required. The automobile parking system design may be modified to accommodate superstructure columns.

LOADING CAPACITY

DRIVE

COATING

1 in Pit 1 above configuration

LOADING CAPACITY

DRIVE

COATING

1 in Pit 1 above configuration

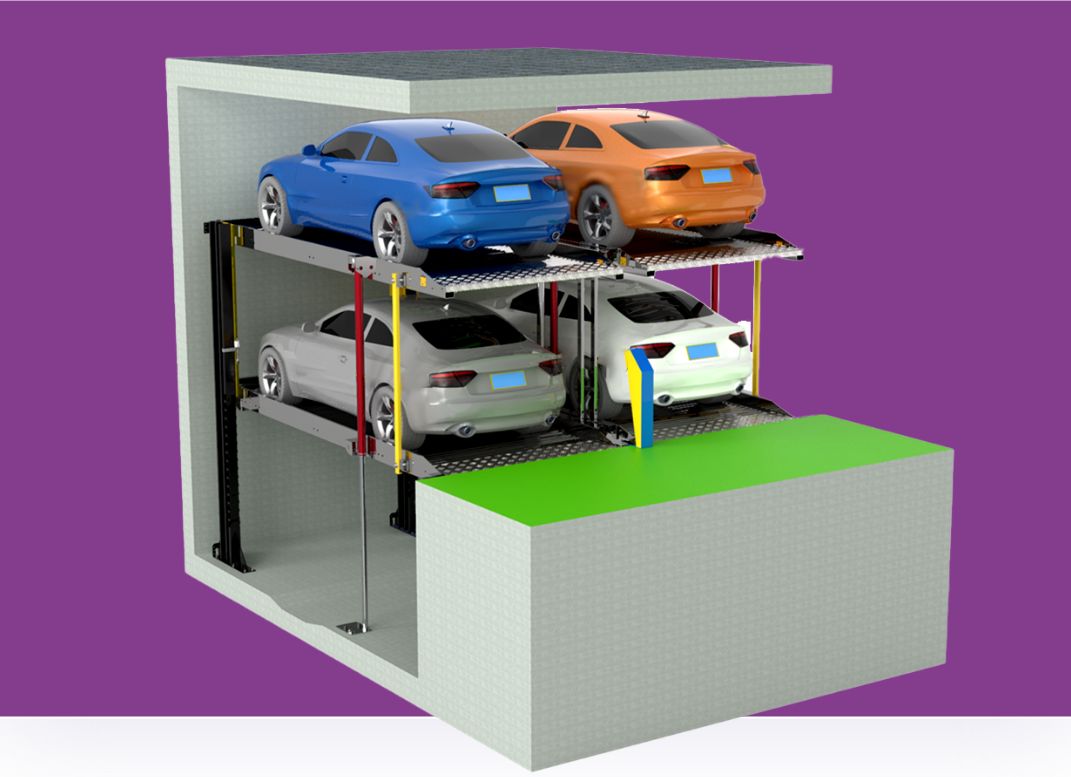

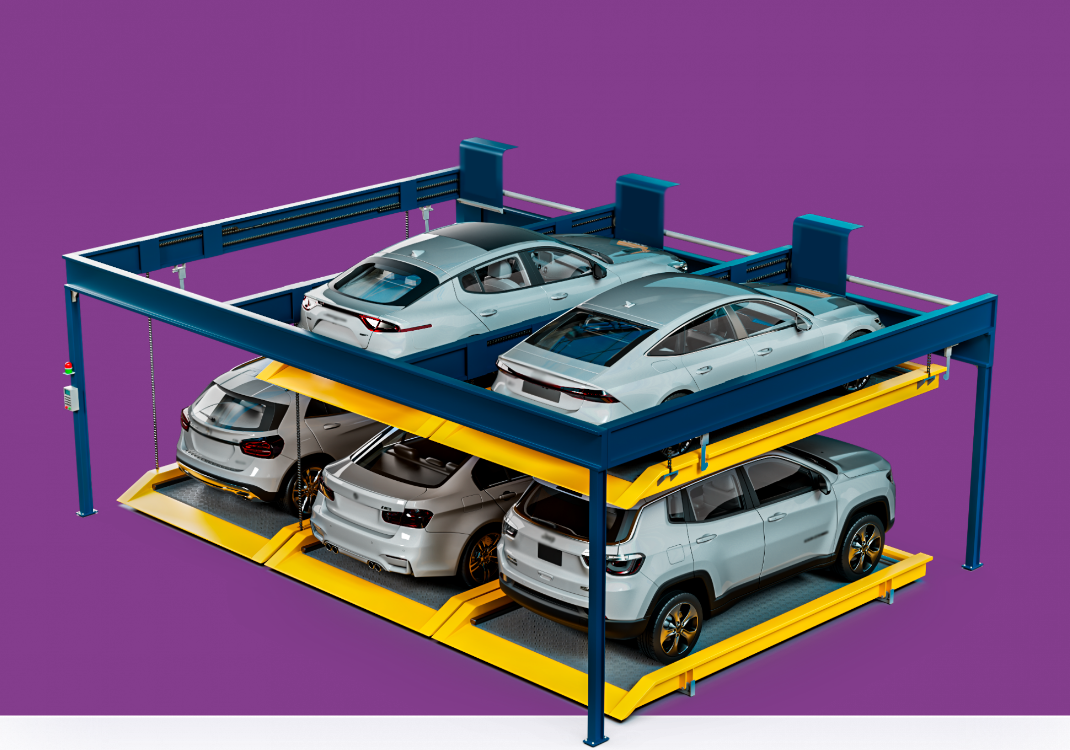

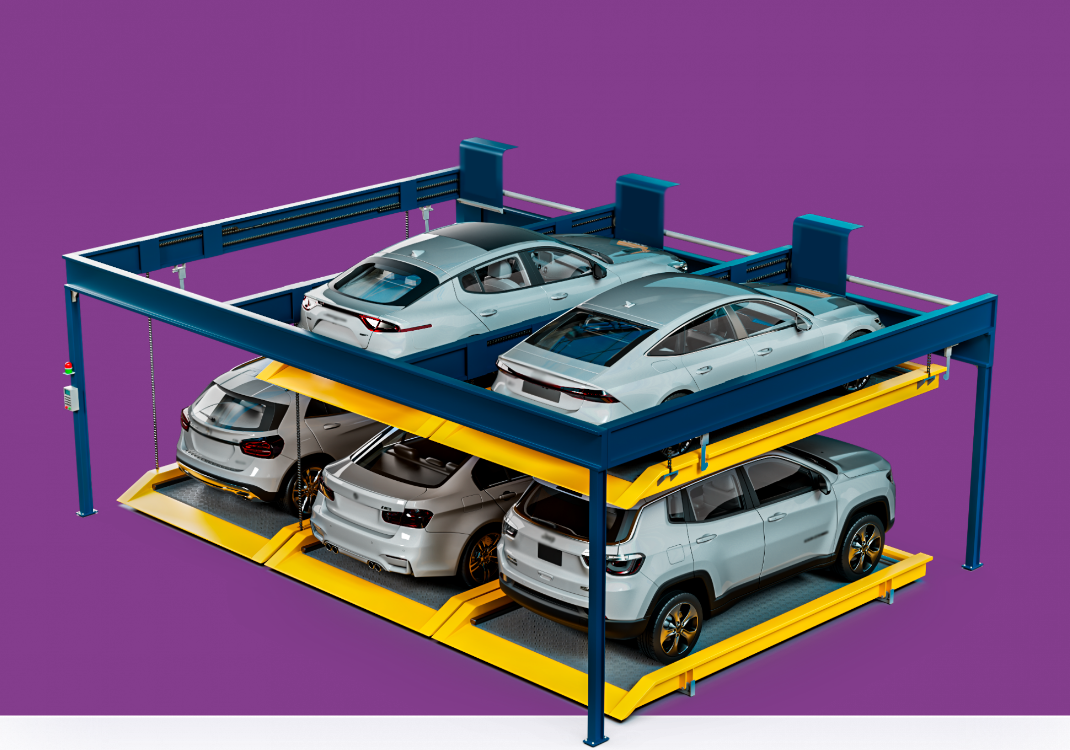

Stackable parking systems have characteristics that distinguish them all.They do not require a pit for installation and the foundation requirements are minimal. Their primary function, as you might expect, is to stack one or more automobiles above ground in a parking area. This permits users to park two or more automobiles in a place that would typically house just one vehicle by utilising vertical space in parking zones that would otherwise go unused. Stack parking systems do this by using moveable platforms that can be raised and lowered using mechanical frames. Cars may park on the platforms and remain stable as workers elevate them to allow more vehicles to park below.

The most basic configuration of a stack parking system is an automobile lift, which comprises two or more columns that move and support the parking platform. These are typically powered by internal hydraulic components and can accommodate two vehicles.

LOADING CAPACITY

DRIVE

COATING

2 stage Pit

LOADING CAPACITY

DRIVE

COATING

2 stage Pit

Puzzle mechanical parking systems are innovative solutions to the problem of restricted parking space. They may increase the number of automobiles in a facility by a factor of two to five.

Puzzle mechanical parking systems are mechanical constructions that can shuffle about various platforms that serve as separate car parking locations. This feature allows for the addition of parking spaces above or below ground.

The puzzle parking device can move platforms vertically and horizontally as well as side – to – side.

Because humans must drive their automobiles into and out of the spots, this parking system is classified as semi-automated mechanical parking. The system can move about its platforms after a car is secure within a place and the driver is free of it.

LOADING CAPACITY

DRIVE

COATING

Over ground puzzle

1,2 & 3 PIT WITH OG CONFIGURATION

OGP OVER GROUND PUZZLE 2 LEVEL

LOADING CAPACITY

DRIVE

COATING

Over ground puzzle

1,2 & 3 PIT WITH OG CONFIGURATION

OGP OVER GROUND PUZZLE 2 LEVEL

Rotary Car Parking Systems are only ideal for outdoor parking, where we may park up to 16 automobiles in the area of three.

The automobile enters the ground level parking bay using this mechanism.

The automobiles are then rotated in a clockwise pattern until an empty bay reaches the ground floor.

To unload a vehicle, all of the cars are turned clockwise until the selected car reaches ground level. The driver now drives the car out of the system, allowing the next car to be loaded or another car to be emptied.

This system may be configured to park any sort of vehicle, from little automobiles to imported vehicles. This system is provided with an auto guidance system and multiple safety sensors as well.

LOADING CAPACITY

DRIVE

COATING

LOADING CAPACITY

DRIVE

COATING

Two-wheeler parking systems are only appropriate for outdoor and basement parking, where we may arrange bikes in layers of 2 to 12. We can ascend three levels for the basement (We need a clear Bottom of the Beam to Floor Height of 6 m).

Three to four motorcycles are put concurrently onto a platform with this arrangement. A puzzle system might be used to park bikes. Three to four bikes are hoisted onto the Platform in a process like a puzzle car parking. Advantages:

More bikes can be stored in a small space because of their limited size.

Best suited for apartments, theatres, shopping centers, and public spaces.

Platform Length

Lifting Height

Lifting Capacity

Power Required

Platform Length

Lifting Height

Lifting Capacity

Power Required